CYCARBON/Production

CYCARBON’s production department fabricates composite parts using a wide range of manufacturing methods, open mold or closed mold.

Fabrication methods and materials are chosen during the engineering preproduction stage in order to achieve the required finished product properties and to stay within budget.

CYCARBON’s manufacturing caters for: Automotive, Defence, Marine, Medical, MotorSport, Sporting goods, Robotics and Industrial using a large number of materials.

Production process.

Understanding the fabrication process.

Mould

Mould is CNC machined or hand made and prepared.

Fabrication

Fabrication of part using chosen method.

Finish

Refinement of composite part, and painting if required.

Delivery

Local and international project delivery.

Depending on requirements CYCARBON will use thermoset and thermoplastic resins.

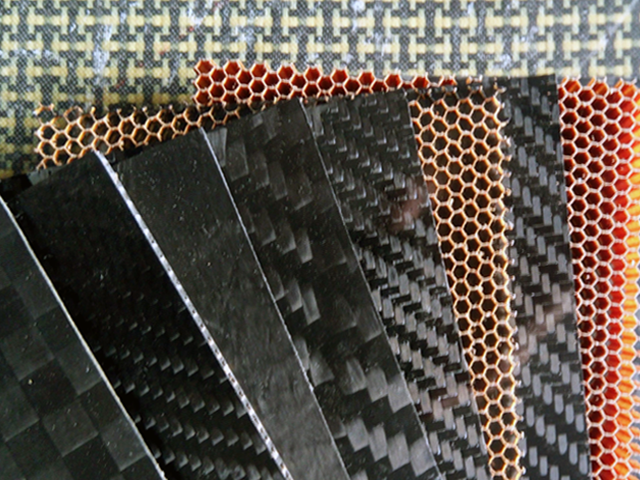

Depending on project CYCARBON will use a number of woven and U.D technical textiles like:

Carbon Fiber, Kevlar®,

Fiber-glass (E-glass, S-glass and (H-glass), and hybrid materials.

When components require a core CYCARBON will use:

Foam Cores,(PVC, polystyrene, Polyurethane, PMI)

Honeycomb (Aluminum, CF,Fiber-glass, Kevlar®, Nomax®)

Key Advantages of composite parts:

- Freedom of shape design.

- Strengthened component geometries can be produced in a simpler way compared to older methods and materials.

- Light construction.

- Flexibility characteristics control.

- Corrosion resistance.

- Good resistance to chemical agents.

- Fire resistance.

- Low density.

- Good insulation.

- Transparency to electromagnetic waves.

CYCARBON also offers low volume production. Find out more.